Establishing an Effective PFAS Treatment Plan

A group of chemicals known as PFAS – perfluoroalkyl and polyfluoroalkyl substances – has been generating a lot of attention. With PFAS in drinking water, public health may be at risk of adverse health effects such as high cholesterol, low birth weight infants, immune-system problems, cancer, and thyroid disease.

Media attention about the topic has grown, and municipal water plants are facing pressure to evaluate PFAS treatment and how to best approach this emerging contaminant in their own water sources.

The Extent of the Problem

Concern over the evidence of PFAS in drinking water has received worldwide attention. An international group of authors created the 2018 Zurich Statement on Future Actions on Per- and Polyfluoroalkyl Substances to encourage collaboration between researchers, regulators, and PFAS users around the globe.

The 2019 Stockholm Convention on persistent organic pollutants required countries to take action to eliminate the production and use of the chemical.

In a recent Harvard study, elevated levels of PFAS chemicals were found in 194 out of 4,864 water supplies in 33 states. Nearly 17 million U.S. residents had perfluoroalkyl and polyfluoroalkyl substances (PFASs) in their water at or above the EPA suggested advisory limit. With this awareness, communities began testing and seeking PFAS treatment options.

In 2016, the EPA established a health advisory level of 70 parts per trillion combined for the main drinking water PFAS chemicals, PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid). With drinking water PFAS measured in the parts per trillion, that is like detecting a grain of sand in an Olympic-sized swimming pool.

Concentration of PFAS in major geographic areas of the U.S.

Image by Hu XC et al., Environmental Science & Technology Letters, 2016. Downloaded Sept. 12, 2019 from What are PFASs, the toxic chemicals being found in drinking water? | PBS NewsHour

Discussions on PFAS removal are heavily centered in areas of the country where drinking water PFAS is a particular problem: the East Coast, the Midwest, and California. Some individual states have adopted their own monitoring guidelines, which contain more restrictive levels than what the EPA suggests.

A Better Understanding of PFAS in Drinking Water

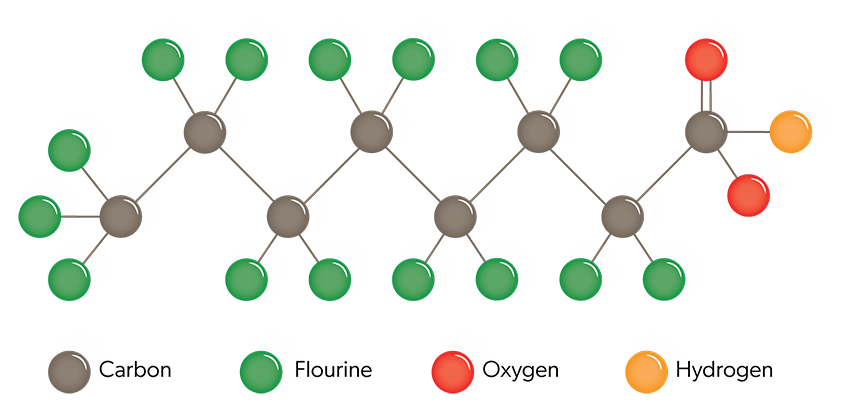

The long chains of carbon-fluorine bonds in PFAS substances (PFOA and PFOS each are comprised of eight carbon molecules with attached fluorine atoms) are some of the strongest man-made chemicals known and are extremely difficult to separate. These bonds are rarely found in nature and are difficult to break down biologically or chemically.

Their use has also contaminated drinking water sources due to the relatively mobile nature of the chemicals that found their way into industrial waste streams.

The two most common types of PFAS substances are PFOA and PFOS, considered “forever chemicals.” These per- and polyfluoroalkyl substances last for long periods of time in people (bioaccumulation) and remain permanently in the environment. The chemical stability that makes PFAS effective in consumer goods also makes these chemicals dangerously persistent in the environment and the human body.

PFAS chemical bond, with long chains of carbon-flourine bonds

PFAS chemicals have been used effectively since the 1950s for manufacturing such things as nonstick cookware, water-resistant clothing, stain-resistant furniture, fire-fighting foam, carpets, and food packaging.

Between 2000 and 2002, PFOS was voluntarily phased out of production in the U.S. by its primary manufacturer. In 2006, eight major companies voluntarily agreed to phase out their global production of PFOA and PFOA-related chemicals. In 2019, the UN Conference of the Parties in Geneva unanimously agreed to a global ban on the use of PFOA.

Considerations for Treatment Choices

The longevity of PFAS compounds and the large number of chemical variations makes their testing and treatment a complicated operation.

While some plants try to avoid treating the chemicals and instead propose drilling new wells, finding new influent sources, purchasing new water supplies, or blending what they have with other sources, removing the chemicals will be the only choice for many plants.

Three treatment solutions are currently accepted as the Best Available Technologies (BAT) to remove PFAS: ion exchange (IX), granular activated carbon (GAC), and reverse osmosis (RO). To choose between them, decisions should be based on two main factors – economics and technology effectiveness.

The decision of which to use will also vary with the circumstances and characteristics of the contamination, such as:

- Length of chemical chain

- Presence of other contaminants or organic matter in the water

- Flow rate and water temperature

- Influent PFAS concentration and desired treatment objectives

Testing for PFAS contamination

The first step in evaluating a PFAS treatment solution is to determine the extent of the problem. In many situations, a plant does not know for sure that it has PFAS, how significant it is, and whether there are other constituents in the water that will need treatment. A large number of chemical variation in PFAS make the testing and treatment of the substances complex.

Learn more about WesTech’s laboratory services

Piloting, in the case of PFAS, is important in determining whether the contaminant responds effectively to a chosen treatment under the plant’s specific conditions and how well it works. It allows a plant to determine the effectiveness of equipment before it is selected for permanent installation. Choosing which EPA-recommended technology – granular activated carbon, ion exchange, or reverse osmosis – will depend on many variables.

Adsorption Options

GAC and IX technologies have been used in water treatment for decades. They are media-based technologies that use a physical/chemical sorption process to remove contaminants. While both GAC and IX have adsorptive capabilities for PFAS removal, IX also has the potential to attract and exchange ions within certain PFAS compounds. Tracking the media is key for the effectiveness of both of these technologies, as the media’s effectiveness is limited, once it is saturated.

The activity of both GAC technology and ion exchange most commonly takes place in pressure filters. On rare occasions, it is used in open basin-style contactors.

The two technologies also have clear distinctives:

Granular Activated Carbon (GAC):

- It has received the most research for PFAS removal, so far, and is most effective as a flow-through filter after particulates are already removed.

- The technology works well on longer-chain PFAS, such as PFOA and PFOS.

- It can remove PFAS along with a range of other contaminants at the same time.

- GAC adsorbents are normally heated to destroy PFAS (usually offsite) and to restore the media’s adsorptive capacity.

- It is a very effective solution, but its success will depend on the type of carbon used, the Empty Bed contact time (EBCT), flow rate, the nature of the PFAS, and whether other contaminants are in the water.

Typical pressure vessel with conical underdrain for granular activated carbon Ion Exchange:

- The technology is engineered to target families of contaminants, like PFAS.

- Resins in ion exchange are single use in PFAS treatment, incinerated when they are saturated, and replaced with new ones.

- Because resins are replaced, the technology does not generate a contaminant waste stream that needs to be treated because the resin in ion exchange is destroyed and does not need to be regenerated.

- For ion exchange, the tiny beads that make up the resin are hydrocarbons. The positively charged anion exchange resins (AER) are effective for removing negatively charged contaminants, like PFAS.

- Ion exchange is effective at removing both long and short chain PFAs, but may be more economically paired with GAC. However, it typically has a smaller EBCT and longer bed life than GAC.

- Ion exchange can also treat nearly all the PFAS within ideal circumstances of flow rate, bed depth, and resin choice.

Example of pressure filters for ion exchange

WesTech is experienced with vessels that support both ion exchange and GAC and offers complete systems, including the media, the vessel or tank, and the piping.

Learn more about WesTech’s vertical pressure filters

Reverse Osmosis and Nanofiltration

In NF/RO treatment, PFAS is rejected by a semi-permeable membrane at high pressure. This produces wastewater that is concentrated with dissolved solids. While a high percentage of the feed water passes through the membrane as clean water, finding a way to dispose of the concentrated reject stream is a consideration with reverse osmosis.

- Reverse osmosis is typically more than 90 percent effective at removing a wide range of PFAS, including shorter chain PFAS.

- While RO is very effective, this technology may require consideration of final water quality, including remineralization steps or pH adjustment.

- Compared to alternate technologies, RO is well suited for water sources with particularly high PFAS concentrations, as it does not require frequent replacement of adsorbents.

As an RO solutions provider with decades of process knowledge and engineering expertise, WesTech provides state-of-the-art, custom RO systems with long membrane life and advanced automation.

Learn more about WesTech’s reverse osmosis solutions

Reverse osmosis membrane filtration system for PFAS treatment

Supplier Solutions

Municipalities are in the process of evaluating their PFAS concerns. Investigating the extent of the problem is the first step. Those closest to military bases or manufacturing hubs are most likely to see PFAS present above the recommended limit, putting those communities at particular risk. These industrial sources of PFAS contamination will also need to address what they can do to prevent PFAS from entering the environment through their wastewater.

WesTech’s broad range of equipment and experience includes many successful municipal and industrial applications for each of the three EPA-recommended technologies, including the necessary vessels or tanks, testing services, rental solutions, and pilot opportunities. WesTech can provide a holistic evaluation and treatment solution that is tailored to the customer’s specific contaminant source and overall treatment objectives.

While addressing PFAS contamination, plants should also consider the need for pretreatment to handle additional contaminants that might be present. For instance, many water sources with PFAS contamination can also have an abundance of organics or iron and manganese, which might require an additional pretreatment step to remove.

Customers who seek out consultation from equipment suppliers that can offer fully integrated solution options for multiple treatment technologies will be better able to effectively manage this emerging, complex issue.