Shrinking Pool of Water and Wastewater Treatment Plant Operators Will Impact the Stability of Clean Water

WesTech EngineeringNovember 3, 2020

A wave of recent retirees has left experienced water and wastewater treatment plant (WTP and WWTP) operators in short supply and high demand. Given 2019 data from the U.S. Bureau of Labor Statistics (BLS) and a recent Time magazine analysis of occupation-based retirement ages, this shortage is set to become even more pronounced.

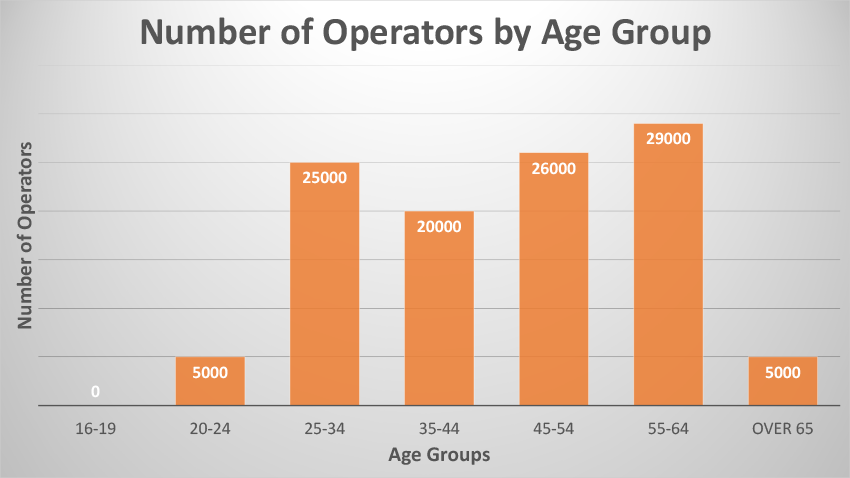

The Time magazine analysis indicates that only 0.91 percent of WTP and WWTP operators – whom the EPA terms water protection specialists – work beyond 66 years of age, while the BLS data shows that over a third of current operations professionals are at, or nearing, retirement age (see the following chart).

Operator demographics per Bureau of Labor Statistics 2019 estimate

Current data suggests the field will lose about 4,550 experienced workers by 2021, and 27,550 by 2031. If the number entering the field remains consistent, the number of workers in younger demographics won’t be sufficient to replace the retirees.

The increasing shortage could impact your plant’s ability to meet the nation’s need for clean water.

Recognizing this, the EPA announced America’s Water Sector Workforce Initiative to support workforce resiliency for water utilities and thereby help ensure that Americans can continue relying on safe drinking water and vital wastewater services that protect public health and the environment. While the EPA and other organizations are putting plans into place, you have several options for mitigating the impact of impending shortages on your plant.

Cross training can reduce the impact of operator shortages.

Options for Ensuring Continuous Water Treatment Services

Here are a few methods of combating operator shortages:

- Actively recruit young people to the field through job fairs and internship opportunities.

- Cross-train operations employees and new hires to cover for colleagues and rotate non-operations employees into various plant operator positions, providing career-path opportunities for those who are interested in plant operations.

- Retool plants with systems, controls, and automation to reduce the number of physical workers required. This can be especially beneficial if your plant is remote, highly depended upon, or inside areas that present dangerous working conditions.

- Enter into an operator-sharing agreement with nearby plants.

- Outsource plant operations to a services organization that offers experienced and licensed operators. Organizations that offer contract flexibility and a range of operations and maintenance services can do things such as:

- Pull quarterly test samples and file compliance reports

- Evaluate, develop, and provide employee training

- Oversee construction

- Develop a contingency plan – or plan B – to address operator shortages resulting from unforeseen disasters such as fires, floods, pandemics, and other conditions (including market forces) that can disrupt continuous operation.

If you determine that outsourcing plant operations is the best course of action, try to select a services organization that provides operators who are experienced with the equipment they will be operating or maintaining (or both). Several equipment design and manufacture organizations offer operations services. WesTech’s team of operator experts have experienced the benefits of this first-hand while working with our customers.

Access to equipment experts helps to quickly resolve problems as they arise.

Carson Judy, one of our lead operators, explains the benefit like this: Having access to equipment experts, in addition to process knowledge, enables us to quickly help and resolve problems when they arise.

Learn how WesTech can provide Plant Operations and Services

Summary

WTP and WWTP plants will soon face a shortage of experienced, certified operations professionals. To ensure that you remain able to provide essential water and wastewater treatment operations, devise and implement one or more of these strategies now, before the impending operator shortage impacts your plant.

References

AWWA: EPA Announces Initiative To Recruit And Retain The 21st Century Water Workforce

Time Magazine: The 50 Jobs Where People Retire the Earliest

U.S. Bureau of Labor Statistics: Labor Force Statistics from the Current Population Survey

U.S. EPA: America’s Water Sector Workforce Initiative: A Call to Action (PDF)